Electroplating

Multinal Group is your trusted partner for electroplating of steel components and products. From semi-finished steel products to final products, we ensure a high-quality zinc coating for optimal protection.

Electroplating applies a thin zinc layer to steel through an electrochemical process, offering corrosion resistance and a sleek finish. To further enhance protection, we apply a passivation layer. Our advanced zinc line (7000 x 1000 x 1300 mm) allows for efficient processing of a wide range of steel components.

Sectors we serve

We provide electroplating for industries including:

- Agrotechnology

- Infrastructure

- Automotive

- Interior and furniture manufacturing

- Chemical industry

- Energy sector

- Machinery manufacturing

- Tank construction

Not seeing your industry? Get in touch—we’re happy to explore solutions with you.

Benefits of electroplating

- Our passivation coatings are CrVI-free and meet REACH and RoHS regulations

- High corrosion resistance

- Thin, precisely applied zinc layers

- Exceptional durability when combined with powder coating

- Smooth, aesthetically pleasing surface

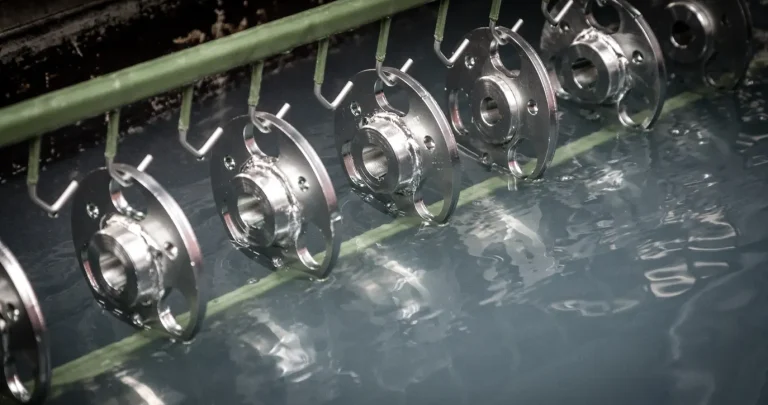

Impression of electrolytic zinc plating at Multinal

Why choose Multinal?

Post-treatments

We can treat the zinc layer with the following passivations:

• Blue passivation

• Black passivation with topcoat

All of these passivations are CrVI-free and comply with REACH and RoHS regulations.

Passivation

In addition to galvanizing, you can choose the type of passivation you want, and we also offer galvanizing in combination with powder coating.

In short, for expert galvanizing or a combination with the surface treatment of powder coating, Multinal Group has the right specialists in-house.

Difference with hot-dip galvanizing

Trusted by our partners

Request a quote!

Discover what precision and partnership can mean for your project. Contact us today for a detailed quote and let’s work together on a solution that exceeds your expectations.