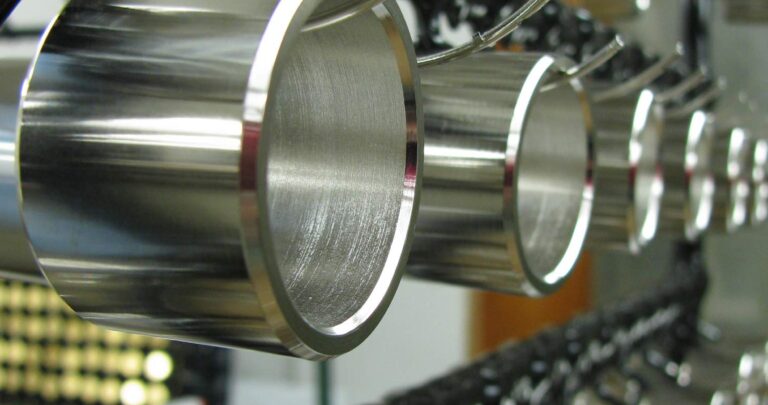

Metal Surface Treatments

When you need the surface of metal objects treated galvanically, chemically, or mechanically, Multinal is the right place for you. Whether it’s hundreds, thousands, or just a few pieces that require surface treatment, Multinal combines traditional craftsmanship with modern techniques, resulting in top quality and an excellent decorative, protective, or corrosion-resistant coating. In addition to a wide range of surface treatments, Multinal also offers pre- and post-processing, packaging, assembly, and transportation.

Advantages of surface treatments at Multinal Group:

- Protection against rust and corrosion

- A sleek appearance

- Decorative or technical coating

- High-quality finish

Our metal surface treatments

-

Pickling & Passivation

At Multinal Group, we understand the importance of delivering premium results for your stainless steel products. With four specialized pickling facilities across the Netherlands, each… -

Electropolishing

Step into the world of refinement and durability with electropolishing—a process that enhances stainless steel surfaces to achieve a flawless, mirror-like finish. At Multinal Group,… -

Electroplating

Multinal Group is your trusted partner for electroplating of steel components and products. From semi-finished steel products to final products, we ensure a high-quality zinc… -

Powder Coating

At Multinal, we believe in long-term partnerships built on trust, quality, and reliability. Our strict quality control and advanced powder coating techniques ensure consistent, high-quality… -

Chrome Plating

Multinal Group offers a wide range of surface treatments, with chrome plating being a popular technique. Known for its decorative appeal and protective properties against… -

Nickel Plating

Looking to nickel plate metal products? At Multinal Group, we provide nickel plating services, whether for a base layer or decorative finish. Nickel plating offers…

Request a quote!

Discover what precision and partnership can mean for your project. Contact us today for a detailed quote and let’s work together on a solution that exceeds your expectations.