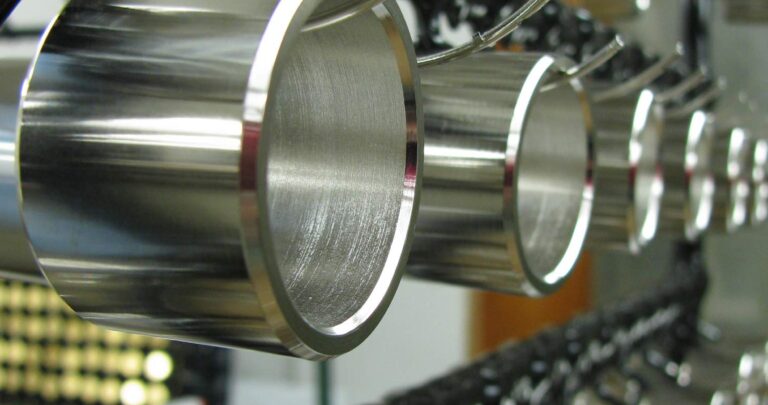

Nickel Plating

Properties of nickel

- Light yellowish deposit

- Highly solderable

- Magnetic coating

- Excellent light reflection

- Variable coating thickness

- Good corrosion resistance

- Non-tarnishing

Industries we serve

We provide nickel plating for sectors including:

- Automotive

- Interior and furniture industry

- Sanitary products

- Lighting

Not seeing your industry? Get in touch—we’re happy to explore solutions with you.

Benefits of nickel plating at Multinal Group;

- Durable protection against corrosion and wear

- Enhanced aesthetic appeal

- Suitable for decorative applications

- Extended product lifespan

- Smooth and easy-to-clean surface

- Combination of functionality and design

- Uniform and consistent finish

Why choose Multinal?

The nickel plating process

Multinal Group often uses nickel plating as a base layer for chrome plating, gilding, or copper coating. This combination of surface treatments enhances each other—the nickel layer gives chrome a beautiful shine, while chrome adds wear resistance and corrosion protection. In addition to being a base layer, nickel can also serve as a standalone decorative coating, offering both functional and aesthetic value.

Coating thickness

The thickness of the nickel layer determines its corrosion resistance. The metal must be pore-free to guarantee good corrosion protection, and not every layer or metal is suitable for this. If corrosion resistance is crucial for you, we can advise you on the best options for your product.

Finish options

- Gloss, semi-gloss, matte, and anti-reflective nickel

- These nickel coatings enhance consumer products or serve as a base layer for chrome, silver, or gold. The finish type is determined by mechanical pre-treatment combined with the type of nickel bath. The duller the layer, the softer and more ductile the nickel coating.

Trusted by our partners

Our partners include:

Request a quote!

Discover what precision and partnership can mean for your project. Contact us today for a detailed quote and let’s work together on a solution that exceeds your expectations.