The difference between pickling and passivation lies in the treatment of stainless steel surfaces. Pickling removes weld seams, discoloration, and other irregularities using strong acids. In contrast, passivation restores the protective layer of stainless steel with a nitric acid solution.

Specialist in Pickling & Passivation of stainless steel

Sectors we serve

We provide pickling and passivation for industries including:

- Food industry

- Pharmaceutical industry

- Nuclear technology

- Agrotechnology

- Infrastructure

- Automotive

- Interior and furniture manufacturing

- Chemical industry

- Energy sector

- Machinery manufacturing

- Tank construction

Not seeing your industry? Get in touch—we’re happy to explore solutions with you.

Benefits of pickling & passivation at Multinal Group:

- Specialization in complex weld assemblies

- Four locations with unique expertise

- Custom solutions for various sectors

- Improvement of product performance

- Strict safety procedures

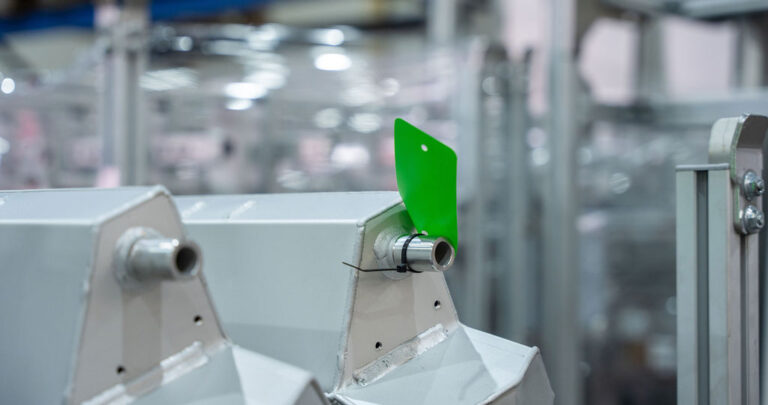

Impression of pickling and passivation of stainless steel

Quality and customization in pickling & passivation

Our clients choose Multinal for our proven partnership and commitment to consistent quality. With precise pickling procedures and meticulous attention to detail, we enhance your products and ensure a flawless finish. Whether handling complex welded structures, large production batches, or specialized industry requirements, we tailor each project to your needs. We also uphold the highest standards for environmental responsibility, safety, and acid residue management.

Reliability and collaboration at the core

Reliability is the foundation of our work. We keep our promises—whether it’s meeting deadlines, maintaining quality standards, or ensuring clear communication. Our dedicated team works closely with you to find the best solutions. Thanks to our flexible approach and short lead times, we consistently deliver high-quality results, both on-site and at our pickling facilities.

Guaranteed expertise and sustainability

At Multinal, we combine years of experience with advanced longevity testing, ensuring the durability and performance of your treated stainless steel products. This makes us the ideal partner for both simple and highly complex projects across various industries.

Trusted by our partners

Our partners include:

Veelgestelde vragen over beitsen & passiveren

Request a quote!

Discover what precision and partnership can mean for your project. Contact us today for a detailed quote and let’s work together on a solution that exceeds your expectations.